220micron UV Hard Coating Anti-scratch Silicone Adhesion Polyester PET Protective Film with PET Liner

Details

220micron UV Hard Coating Anti-scratch Silicone Adhesion Polyester PET Protective Film with PET Liner

Product Details on 220micron Anti-scratch PET Protective Film

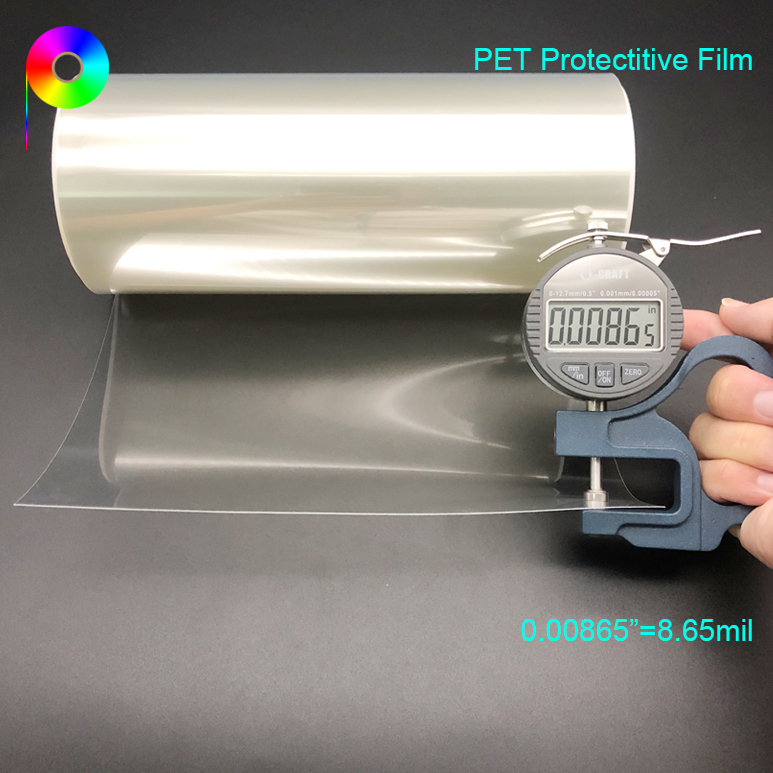

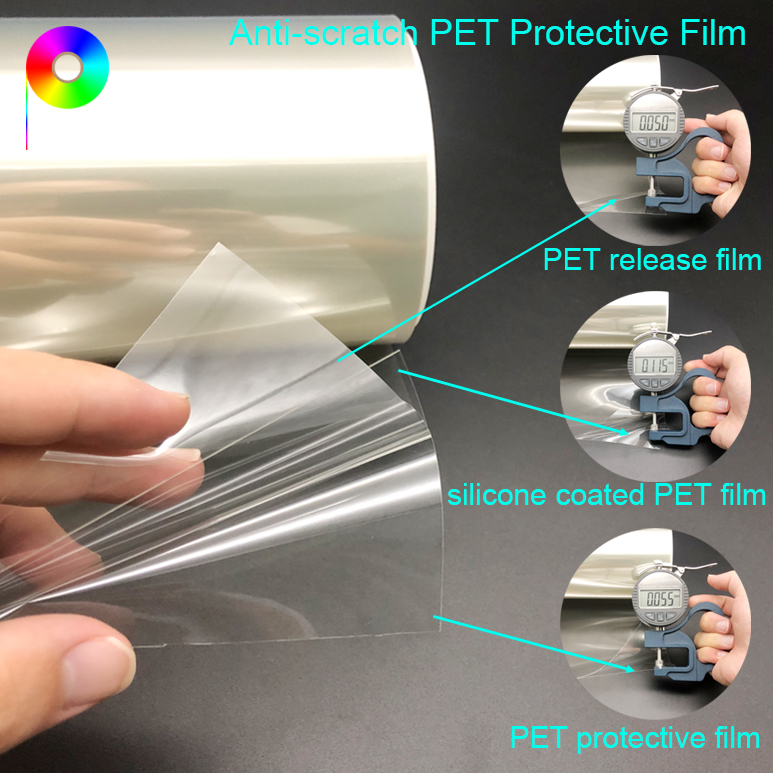

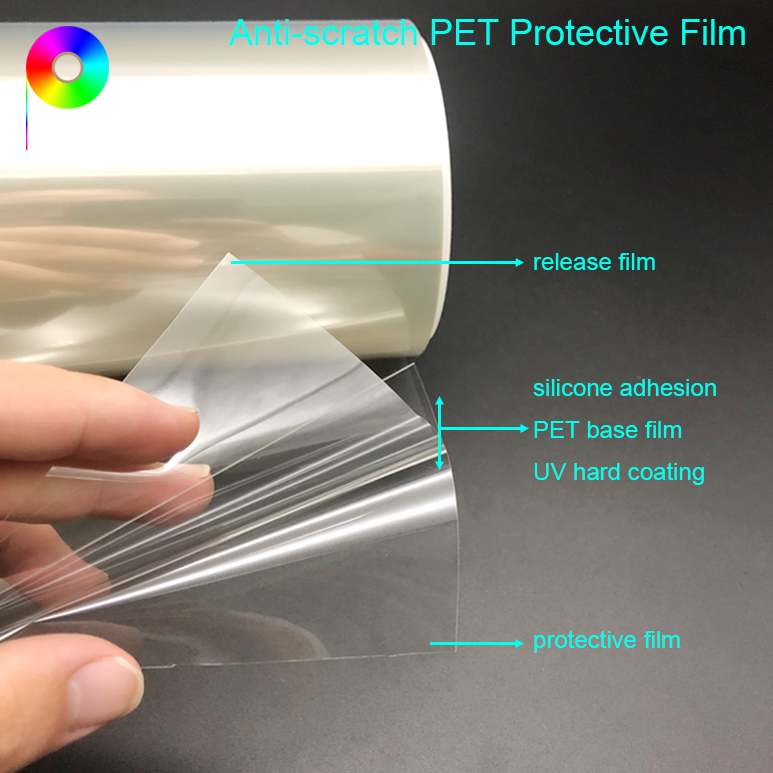

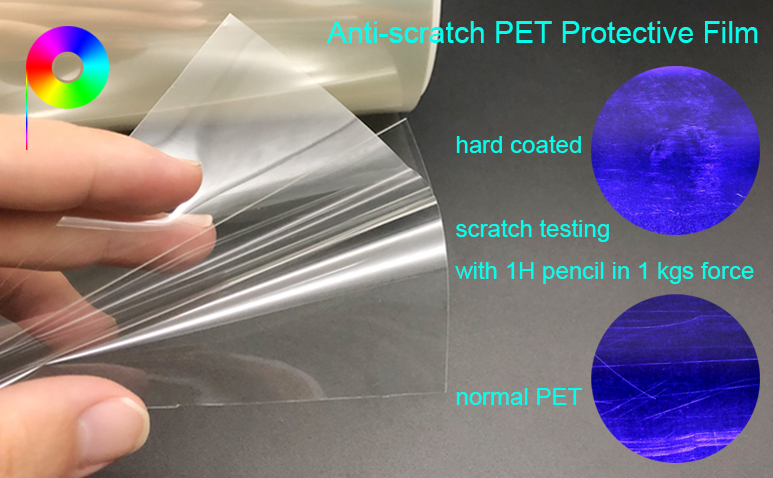

Anti-scratch PET protective film is a protective film with hard coating on the optical PET film, which protects the PET film from scratching.

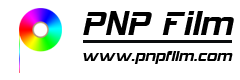

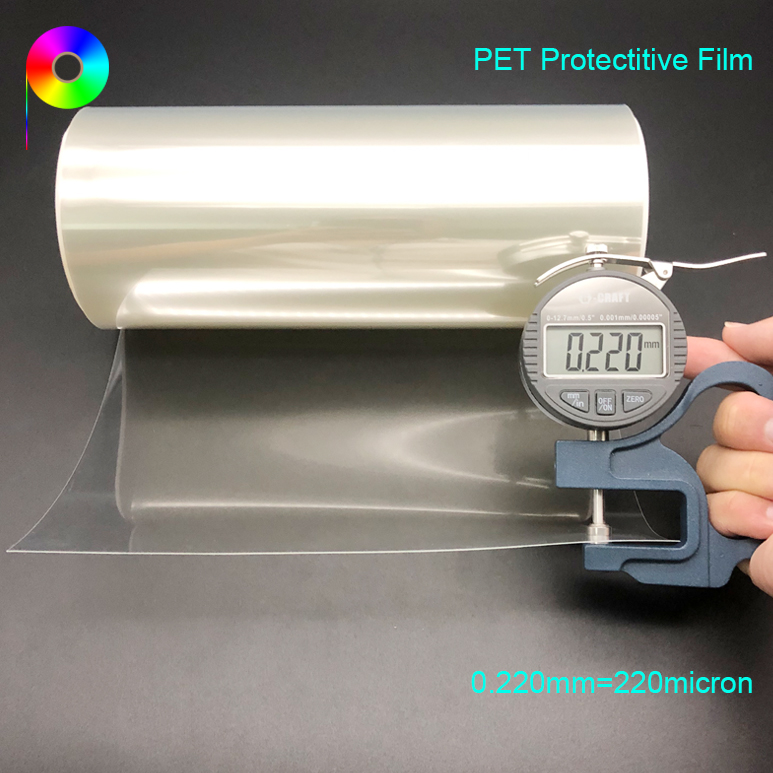

220micron scratch free PET protective film takes 100micron PET film as the base film. It is coated with 13micron silicone adhesion on the inner side and 2micron of UV hard coating is processed on the outer side. After the 2 coatings, the thickness of usage layer would reach 115micron. Then it would be protected by PET liner on both sides.

Anti-scratch PET protective film is mainly used for screen protection such as LCD screen and process protection such as laser engraving cutting.

|

Technical Date Specification of Anti-scratch PET Protection Film 220micron |

|||||

|---|---|---|---|---|---|

| Thickness: | 220 ± 5 micron | Width: | 1040mm/custom | Length: | 200m/custom |

| Appearance: | transparent | Light Transmittance: |

≥ 90% |

Haze: | 0.8% |

| Temperature Resistance: | -20℃~150℃ | Hardness: | 3H |

Shelf Life: |

12 months |

| Adhesion: | 3 g/25mm adhesion on the protective film side, and 20 g/25mm adhesion on the silicone adhesion side | ||||

| Storage Conditions: |

temperature 10~36℃, relative humidity 40%~70%, prevent direct light, good ventilation |

||||

What Is Protective Film?

In terms of function, the protective film is to put a film on the physical objects we want to protect. It helps for reducing the loss of surface scratches encountered during the transportation, handling, storage and even display of products in the circulation link from the factory to the market. According to the application scope, the protective film is mainly used on the surface of metal products, coated metal products, plastic products, automotive products, electronic products, sign products, and other products.

Where Is Protective Film Used?

Protective film has a wide application field. According to usage, protective films can be divided into digital product protective films, automotive protective films, household protective films, food preservation protective films, etc. According to market classification, the protective film is mainly used on the surface of metal products, coated metal products, plastic products, automotive products, electronic products, sign products, and other products.

According to market classification, protective films can be divided into traditional protective films(such as galvanized steel plate protective film, color steel plate protective film, glass plate or plastic sheet protective film), protective films for flat panel displays(flat panel display, TFT-LCD module, backlight module, glass substrate and various optical components such as polarizing plates and color filters), and protective films for high-tech electronics(dry film process, wafer grinding process).

How to Select a Suitable Protective Film?

With the development of technology, the protective film is mostly innovated upon demand's side, which brings out a situation that there are lots of protective film types.

PE, PVC, PET, and PU type protective film take up the most market share among the protective film. While demand differs from each project, such as applying material(glass, plastic, metal, etc), surface property(such as glossy, frosted, coats, roughness, etc), subsequent processing technology(stamping, cutting, bending, punching, etc), other specific demand(use environment, storage and transportation conditions, outdoor requirements, substrate color, printing demand or not). So a sample for testing after the discussion is the most popular method for selecting a suitable protective film. Welcome to contact PNP Film(Email: info@pnpfilm.com, Telephone/WhatsApp/WeChat: +8617306017582) for confirming the suitable protective film now.

| Contact : | PNP Film |

|---|---|

| Phone : | +86 17306017582 |

| Email : | info@pnpfilm.com |

| Skype : | +86 17306017582 |

| Wechat : | +86 17306017582 |

| Address : | Room 209, No. 12, Huaguang Road, Huli District, Xiamen |