What Is Corona Treatment of a Plastic Film?

- 2020-01-01

- Original

- 4890

What Is Corona Treatment?

Corona treatment is a kind of electric shock treatment, which makes the surface of the substrate have higher adhesion.

What Is the Purpose of Corona Treatment?

The purpose of corona treatment is to change the surface energy of many substrates and make them easy to bond with printing inks, coating materials, and adhesives.

Why Is Corona Treatment Required?

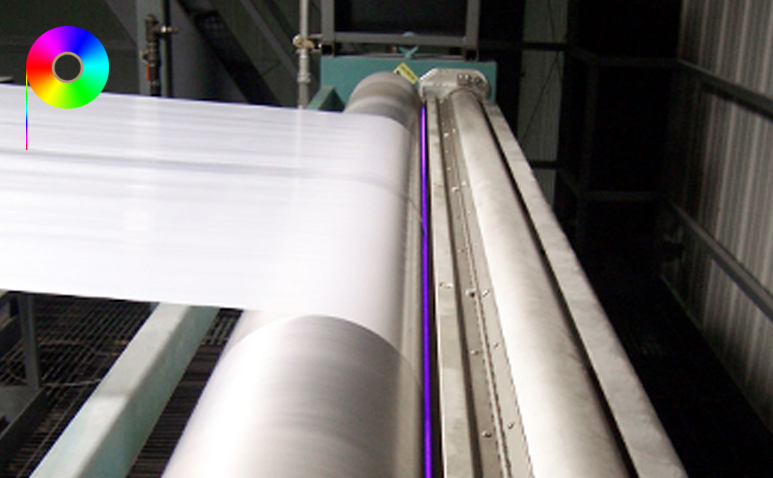

Most plastic films (such as polypropylene films) are non-polar polymers with low surface tension. Known inks and adhesives cannot adhere firmly to them. Therefore, the surface should be treated by the corona method to break and degrade the chemical bonds of plastic molecules, increasing the surface roughness and surface area.

In addition, a large amount of ozone is also produced during discharge. Ozone is a strong oxidant, which can oxidize plastic molecules to produce carbonyl groups and peroxides and other polar groups, thereby increasing its surface energy.

What Is the Principle of Corona Treatment?

The principle of corona treatment is to use high-frequency and high-voltage corona discharge (high-frequency AC voltage as high as 5000-15000V/m2) on the surface of the plastic to be treated to generate low-temperature plasma, which causes a radical reaction on the plastic surface to make the polymer cross-linking occurs. The surface becomes rough and increases its wettability to polar solvents.

These ionic bodies break their molecular structure by electric shock and penetration into the surface of the printed body and then oxidize and polarize the surface molecules to be treated. The ion shock erodes the surface, thereby increasing the adhesion ability of the substrate surface. Ion electric shock corrodes the surface, which increases the adhesion of the substrate surface.

How To Test or Evaluate the Corona Treatment?

The dyne test pen (38 mN/m) can be used as a quick test tool for the surface energy after corona treatment. When the test pen draws a line on the corona treated surface, if it is a continuous line, it means that the surface energy of the material is not less than 38mN/m. If the material is intermittently not connected in a line, it means that the surface energy of the material is less than 38mN/m, and the treatment is insufficient or even untreated, which does not meet the printing processing requirements.

Why is Second Corona Treatment Required?

After corona treatment, the cross-linked structure of the plastic surface layer is less than the cross-linked structure of the inner layer, so the functional groups of the surface layer have higher mobility. Therefore, many plastics experience a decline in the corona treatment effect during storage(such as more than 1 year). In this case, secondary corona treatment is required. It can remove the dirt on the film surface, which not only helps to improve the adhesion of the printing ink but also improves the visual effect.

Welcome to contact PNP Film or send us an inquiry for further discussion if any questions or doubts about plastic film, lamination process, etc.